Shine Tiffany Quality

Situational Challenge:

Global Quality Management at this iconic jeweler was completely inspection based resulting in reactive defect fixes and proving the rule of 10: Correcting a defect costs 10 times more than finding it in the previous stage. Overall, this increased operational costs and customer returns, with non-standardized global processes, limited manufacturing feedback to design, and sub-optimum supplier quality. The need was for a strategic, analytics, and risk based global quality management.

Strategy and Action:

What

- Collaborated globally with front-line associates, global vendors, various functions, and executive leadership to assess the current state, and define the problem, scope, and timeline.

- Developed a measurement, data gathering, an analysis process for quality measures for product quality, manufacturing quality, vendor goods quality, returns and service quality.

- Determined current baselines: process, skills, productivity, costs, margins, quality.

- Developed five key strategic focus areas in alignment with corporate goals for revenue growth, margin improvement, and social responsibility: Risk Management, Global Total Quality Management and Process, Quality Information, People, Maintenance.

Where

- Full stream risk management of gemstones.

- Upgrade merchandise testing laboratory to state-of-the art.

- Local, in-country, training for jewelry service and repair.

- Ground-up, Quality capability for Tiffany Watch Company, Switzerland.

- Governance process for joint Design-Manufacturing-Service-Quality requirements.

How

- Implemented full stream gemstone risk identification and mitigation.

- Completed various technology and equipment upgrades to the merchandise testing laboratory.

- Led oversight of new global Supply Chain system implementation.

- Deployed Latin America and Asia in-country local jewelry service and repair training.

- Assess and enhance staff skills vis-à-vis requirement.

Results:

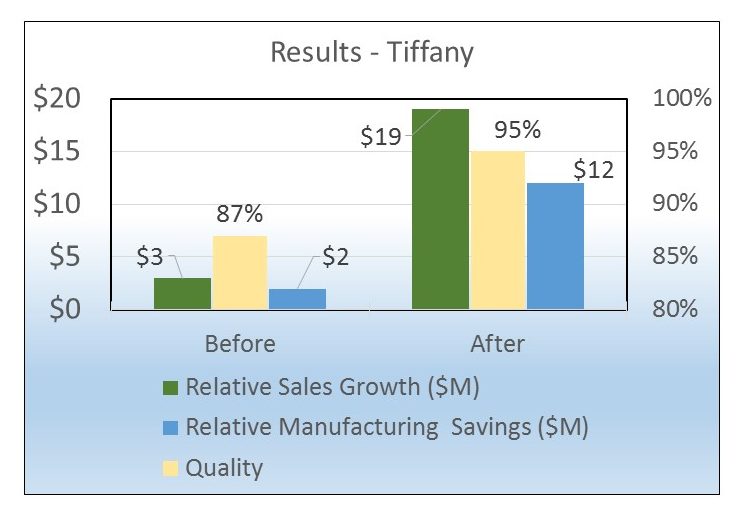

- Implemented a 3-Year Strategic Plan, restructured organization, and guided company through transformative structural and culture changes.

- Drove Demand Management and Inventory Optimization yielding a $16M (4%) YOY Sales growth.

- Established a state-of-the-art Quality facility at Tiffany Switzerland, $100MM 3 year revenue target.

- Achieved a $10M yearly Manufacturing cost savings, 95%+ yield, and 100% Risk reduction from synthetic stones.

- Deployed Design-to-Service and supply chain synergy with robust Critical-to-Quality and Quality at the